Hydrochloric acid recovery

HCl Recovery

Discover the true power of a high-speed, sustainable pickling solution. Not just industry-leading acid recovery; this is industry-defining.

Acid recovery using vacuum evaporation.

Heavy metals and contaminants slow your pickling process (also leaching or ion exchange) and waste valuable acid. Our systems meticulously remove impurities and render your acid* truly new again.

*Note that the HCl Recovery System is flexible enough to recover certain mixed acids.

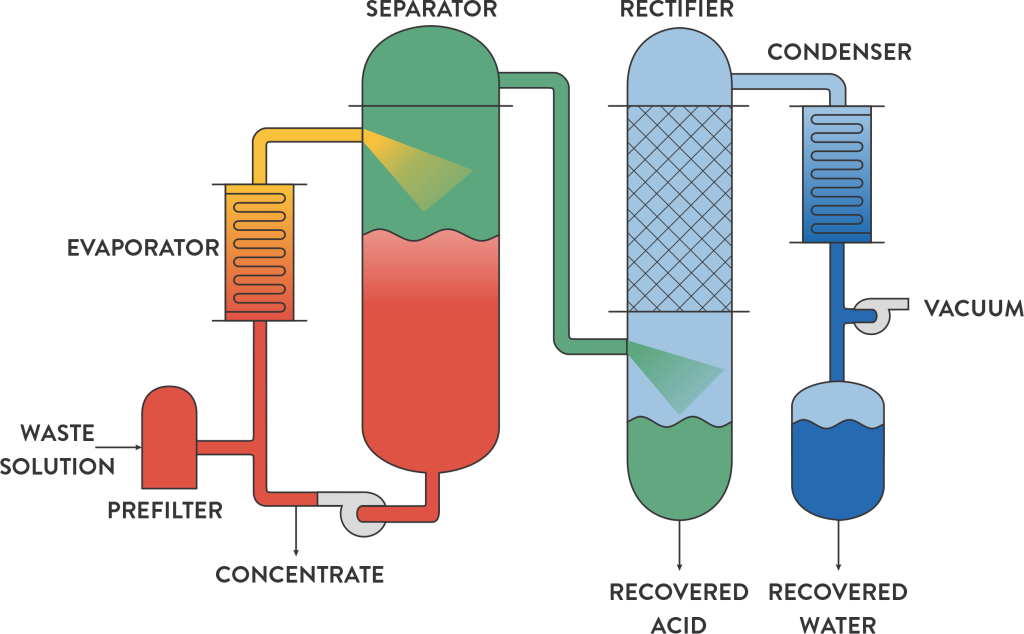

Spent acid is pumped through a pre-filter into an evaporation loop, comprised of:

a.) Centrifugal Pump

b.) Evaporator Exchanger

c.) Separator Tank

The Separator Tank vaporizes the acid and water while the metals remain in solution.

As the temperature increases in the evaporation loop, a concentrate stream of metals exits through a port at the back of the system.

The recovered acid and water vapors travel to the Recovered Acid Tank where the acid cools to liquid form and exits the process.

Water vapor at the top of the Rectifier continues its journey into the Condenser where it is condensed to liquid for reuse.

Our philosophy

Acid recovery—one size does not fit all.

Discover how we tailor and streamline your process to eliminate needless waste at every step.

The outcome? An ROI in less than 2 years.

Need something perfectly fitted to your space?

Others may say “tough luck.” We say “fun challenge.” Our relentless team of experienced engineers are happy to work with any space constraint, and generate 3D models of our systems in your real-world space.

small

medium

large

Models 2MT – 4MT

Models 5MT – 15MT

Models 20MT – 35MT

7.8’ x 5.3’ x 16.5’

12’ x 7.5’ x 22.5’

15’ x 7.6’ x 24’

2.4m x 1.6m x 5m

3.7m x 2.3m x 6.9m

4.6m x 2.3m x 7.3m

Length x Width x Height

Beyond the installation

Seamless integration.

Remote control

Monitor and manually control your entire operation from anywhere with a computer or phone using our dedicated app.

Assistance anywhere

Beta engineers can monitor your system around the world to provide troubleshooting. You’re never left long waiting for a response.

Truly Automated

Our proprietary software automatically analyzes operating conditions and initiates tasks without you needing to lift a finger.

Join hundreds of installations worldwide.

Since 1980, we’ve been pushing the limits of engineering across the world for operations in any industry.

Join our community and see for yourself the Beta difference.

Discover more.

Browse our files to learn more about our HCl Recovery systems.