Hydrochloric and Mixed Acid Recovery

You are here

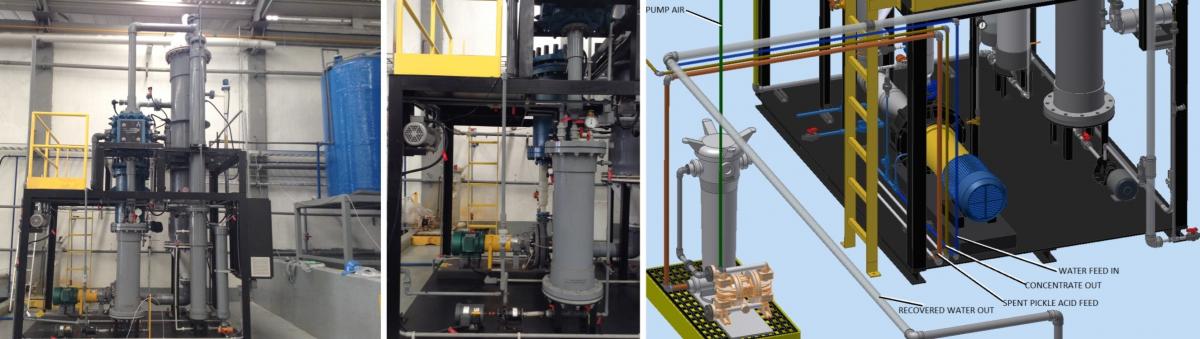

Both our Hydrochloric and Mixed Acid Recovery Systems use vacuum evaporation to remove iron from the inactive, spent acid. Vacuum evaporation has proven more efficient than atmospheric evaporation because its lower operating temperature (80 dC vs 120dC) extends the life of the components and uses less natural gas.

Hydrochloric Acid Recovery

Typical spent acid streams entering the HCl Recovery System: 6% HCl, 8% Fe, and 0 - 2% Zn. Variations on these percentages are also applicable. Our system separates the HCl and water vapor from the metals to yield a return acid stream of approximately 16 - 18% HCl.

Mixed Acid Recovery

Beta's Mixed Acid Recovery System recovers waste acid mixtures of HF/HCl and HF/HNO3 safely and efficiently. Plus, often the metal contamination, such as titanium, in these mixed acids is quite valuable, so their recovery yields a significant savings.